How clean does it burn?

You will hardly see any smoke coming from the exhaust stack for some waste oils! WVO burns the cleanest and I saw no smoke coming from the stack when I burned it. Next is waste transmission fluid and last would be waste motor oil where you see some smoke depending on what all is in the waste motor oil. The design used in this project is basically the same method being used in commercial waste oil heaters which are EPA certified in many USA states. However, commercial waste oil heaters can cost thousands of $$$.

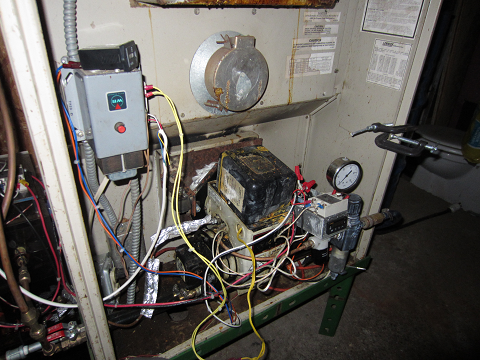

Here's some pictures of a modified burner.

Here you can see where the pressure gauge, air filter, electrical air solenoid, PID controller and SSR are mounted. The air filter is black object with the round knob on top just under the pressure guage. The SSR is above the PID controller and the air solenoid (notice the copper tubing going to the burner nozzle) is below the PID controller.

On the side of the furnace is mounted my first prototype Constant Level/Preheat Tank made of plexiglass. Notice it has waste motor oill in it. I also added a couple of small valves (red handles) so I can shut off the feed & return fuel lines so it's a bit easer to remove the burner when needed. There are also some quick disconnects on the wiring between this tank and the burner so that removing the burner is easy. The dark plastic tray on the floor is because I have an occasional drip from a plexiglass seam which I tried to patch with some red RTV silicone. I accidentally overheated the tank above 300F when setting things up. Plexiglass does not like very high temperatures. The new metal tank should be much better on the next one I'm building. Notice the PID controller mounted on the top left of the tank and on the top right the SSR is mounted on a piece of scrap 1/4" steel plate (on standoffs) which helps keep it cool.